- 2-Zone/ 3-Zone Stationary Specimen, Exposure By Cooling Air/ Hot Air Changeover.

- The machine is divide into three sections: the high temperature chamber, the low temperature chamber and the testing chamber.

- The color touch panel control system was made in Japan can display Chinese / English. The big size liquid-crystal LCD (320X240) has been adopted.

- High formula memory capacity may be set to 100 patterns. the maximum cycle setting is 9999 cycles. The maximum setting of each section is 999Hrs 59Mins.

- Provided with RS-232C communication interface device, capable of controlling/ editing/ editing recording in line linkage with the computer and two set dynamic connection point (TIMER SIGNAL REPLAY) and convenient application.

-

Features

Features -

Features

Features- Strong counter-rotating mixture of high and low temperatures.

- Features automatic positioning in both horizontal and vertical axes, plus pre warming, pre-cooling and recording of shock results.

- Uses the Garden DO2ts heating oil in hot and cold chambers to minimize the costs of oil changes.

- Large LCD (320 x 240 dots) with Chinese / English display of temperatures, with programmable mini-computer control system.

- This system is suitable for on-site use with choice of water cooling or air cooling.

-

Features

Features- Stainless steel #304 interior and painted galvanized steel exterior for long life and beautiful appearance.

- Fitting the large number or volume testing.

- Power all linking control to provide the best safety.

- The internal volume may be randomly enlarged and contracted which design is depending on the environmental requirement of the user.

- And the move would be many fast when customer want to changer to another factory

- Adopt the Japanese Micro-Computer control system of English/ Chinese display with big size LCD (320*240 dots(. High function and simple to operate.

- Provide with RS-232 communication interface device, capable of linking with a computer to control, edit, record, and connect timer signal delay

-

Features

Features- Visual Range Up to 20 Meters

- High Accuracy

- Display temperature and humidity

- Reliable and stable sensors

- Calibration Function

- External Power and Wall Hanging

- Optional Accessories: Light, Sound, GSM Alarms

- PC Software ToMonitor + ToClient Software Management System

- 4 keys, could set deviation, Set upper and lower limits of the alarm

-

Features

Features- Non-contact measurement.

- Suitable for flow inspection.

- Work with clamp-on sensors.

- Velocity range : 0 ... ±10 m/s

- Pipe size : DN15 ... DN6000 mm

- Liquid temperature : -30 ... 160°C

- Accuracy : ±1%

- Liquid type : Water, sea water, waste water, alcohol, beer, various kinds of oil etc which can conduct ultrasound single uniform liquid

-

Features

Features- Compact size

- RH accuracy up to ±1.0 %RH

- Temperature accuracy up to ±0.2 °C (0.36 °F)

- Temperature measurement range −40 … +60 °C (−40 … +140 °F)

- Chemical purge provides superior chemical resistance

- Modbus RTU over RS-485

- Compatible with Indigo series transmitters and Insight PC software

- Traceable calibration certificate: 6 points for humidity, 1 point for temperature

-

Features

Features- RH accuracy up to 0.8 %RH, Temperature accuracy up to 0.1 °C (0.18 °F)

- Temperature measurement range -70 ... +180 °C (-94 ... +356 °F)

- Operating pressure 0 ... 10 MPa (0 ... 100 bar)

- Sensor purge provides superior chemical resistance

- Modbus RTU over RS-485

- Plug & play compatible with Indigo series of transmitters

- Traceable calibration certificate: 5 points for humidity, 1 point for temperature

-

Features

Features- RH accuracy up to 0.8 %RH, Temperature accuracy up to 0.1 °C (0.18 °F)

- Temperature measurement range -70 ... +180 °C (-94 ... +356 °F)

- 250 mm (9.84 in) probe allows easy process installation through insulation

- Sensor purge provides superior chemical resistance

- Modbus RTU over RS-485

- Plug & play compatible with Indigo series of transmitters

- Traceable calibration certificate: 5 points for humidity, 1 point for temperature

- Sintered AISI316L filter standard in delivery

-

Features

Features- RH accuracy up to 0.8 %RH, Temperature accuracy up to 0.1 °C (0.18 °F)

- Temperature measurement range -70 ... +180 °C (-94 ... +356 °F)

- Vapor and pressure proof construction

- Probe and sensor warming functions minimize condensation on probe

- Sensor purge provides superior chemical resistance

- Plug & play compatible with Indigo series of transmitters

- Modbus RTU over RS-485

- Traceable calibration certificate: 6 points for humidity, 1 point for temperature

-

Features

Features- Miniature probe head with low thermal mass for superior response time

- RH accuracy up to 0.8 %RH

- Temperature accuracy up to 0.1 °C (0.18 °F)

- Temperature measurement range −40 … +120 °C (−40 … +248 °F)

- Sensor purge provides superior chemical resistance

- Modbus RTU over RS-485

- Compatible with Indigo transmitters and Insight PC software

- Traceable calibration certificate: 6 points for humidity, 1 point for temperature

- M10×1.5 cable gland included for mounting the probe head

-

Features

Features-

Six models for demanding industrial applications

-

Full 0 ... 100 %RH measurement, wide temperature range -40...+180 °C (-40...+356 °F)

-

Pressure tolerance up to 100 bar

-

Excellent performance in harsh conditions; good chemical tolerance

-

Corrosion-resistant IP65/IP66 housing

-

5-point calibration (certificate included)

-

Two analog outputs, calibrated (certificate included)

-

RS232, ASCII output

-

-

Features

Features- Intrinsically safe (Exi) for operation in up to Zone 0 / 20

- Measures RH and T and outputs an extensive range of calculated parameters: for a full list, see Technical data (page 5).

- Designed for harsh conditions

- Temperature range between −70 … +180 °C (−94 … +356 °F) depending on the probe option

- Vaisala HUMICAP sensor features high accuracy, excellent long-term stability, and negligible hysteresis

- Display options: graphical LCD display and non-display model

- Traceable calibration (certificate included)

- Compatible with Vaisala Insight PC software

-

Features

Features- Generates stable humidity and temperature conditions (<+-0.1% RH, <+-0.01 Degree Celsius)

- Calibration solution for the laboratory and on-site

- Humidity equilibrium typically in only 5 minutes for HG2-S, 15 minutes for HG2-XL

- Calibrate multiple probes simultaneously

- << Auto >> Automated calibration optional

- << Remote API >>logging and control with third party software (optional)

- Integrated FDA 21 CFR part 11 compliant Rotronic HW4 software

-

Features

Features- Numerical and graphical color display for up to 3 parameters

- IP65 metal housing

- Support for one Indigo compatible probe

- Tool-free locking wheel for the probe

- 24 V AC/DC power supply input

- 3 pre-configured analog outputs (mA or V)

- Service port on the front for connecting to Vaisala Insight PC software or Indigo80 handheld indicator

-

Features

Features- New & improved petroleum resistant scale, makes it easier to read.

- Choose 10 liter capacity fuel test measure cans.

- Provides a calibrated measure for testing the accuracy of fuel dispensing equipment.

- Stainless steel construction.

- Suitable for use with diesel proving can, biodiesel, petrol & AdBlue

- 304 stainless steel construction.

- Filling the measure to the “zero” mark will ensure an accurate amount of liters has been dispensed allowing the dispenser to be calibrated accordingly

- Full range of spares available on request

-

Features

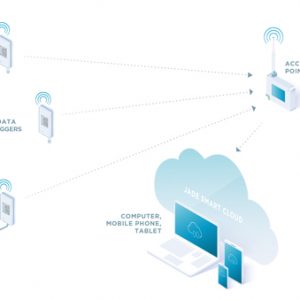

Features- Online service for monitoring of measurement parameters such as humidity and temperature

- Secure cloud storage of data

- Management of measurement locations using an intuitive system of sites and locations

- Connect using a web browser on your mobile phone, tablet or computer

- Add devices and users based on your needs

- No device pairing needed, as devices are associated with a specific cloud account when they are purchased