Skip to content

Features

Calibration of both temperature and pressure transmitters

Measure/source/simulate mA loop parameters

Measure and source mA, Volts DC, frequency, and resistance

Built-in 24 V loop power supply

Store and recall frequently used calibration set ups

Features

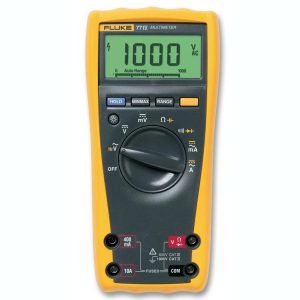

Large display

Backlight for work in dim areas

Min / Max to record signal fluctuations

Ergonomic overmolded housing with integrated probe holders

Free your hands with the optional TPAK magnetic hanger

Auto and Manual ranging

Meets Measurement Category 1000 V CAT III and Category IV 600 V safety standards

Features

Identify complex signal problems fast

Supports accurate measurements on VFDs using a low-pass filter

Captures intermittents as fast as 250 µS with Peak Capture

Features

Test the safety and functionality of AC electrical vehicle charging stations with the all-in-one solution

Pass/fail test results

Auto control pilot (CP) with waveform analysis

Compatible with TruTest™ Data Management Software

Features

One pair (red, black) comfort grip probes with silicone insulated, right-angle test leads

Recommended for µV measurements

CAT II 1000 V, 10 A rating

CAT III 1000 V, CAT IV 600V only with protective cap

Features

Quickly configure, start and stop tests on the 1555 remotely, a safe distance away from any operating, energized equipment, using Fluke Connect® and a smart phone

Real time trending gives you easy-to-see visual cues, rather than hard to read, rapidly changing values

Report creation using Fluke Connect desktop saves time and makes test results easier to understand

Fluke Connect saves test results to the cloud for analysis and preventive maintenance

Features

Measurement accuracy 1%

Converter IP rating IP 67, transducer IP rating IP 68 Wide measurement range, pipe size from DN15 mm to DN6000 mm Connect the temperature transducer can finish the heat / energy measurement

Main Function

Embedded run/stop switch, motor on/off, load run, auto-stop, manual stop, operation delay, load delay, embedded timer

Pressure / temperature high level

Temperature low level (standby for starting)

Interlock input signal (emergency switch, OCR reverse phase)

Usable thermometer and manometer

RS485 communication (MODBUS)

Main Function

Embedded run/stop switch, motor on/off, load run, auto-stop, manual stop, operation delay, load delay, embedded timer

Pressure / temperature high level

Temperature low level (standby for starting)

Interlock input signal (emergency switch, OCR reverse phase)

Usable thermometer and manometer

RS485 communication (MODBUS)

Main Function

Total control and detection (protection) for freezers

Function of start, restart, pump down, alarm delay timer

Discharge gas detection (high & low temperature)

Individual alarm message (OC, HP, LP, OP, INT)

RS485 communication (MODBUS)

Main Function

PID degree of superheat control through defense and safety compensation

Degree of superheat control for various refrigerant

PMW (opening ratios control)

Remote operation

Transmission output

RS485 communication (MODBUS)

Main Function

3 stage fan speed controllable

4 kind (stop / high / middle / low) airflow choosable

Unification of temperature control function

Data backup

Self diagnostic

RS485 communication (MODBUS)

Main Function

Defrosting (auto / manual)

Fan control

Efficient delay

Room temperature sensor: 1EA

Defrost sensor: 1EA

High (low) temperature alarm output

Room temperature transmission output (4~20 mA)

RS485 communication (MODBUS)

Main Function

Efficient defrosting in geothermy heat pump system

Defrosting execution by measuring of ambient humidity and temperature

Main Function

Output controllable based on measured pressure value (increase and decrease)

Alternative operation available between freezing exclusive model and booster

Pump unit control model

RS485 MODBUS

Main Function

Uniform step control

Operation with intelligent shift high / low alarm output

Sensor correction / Sensor error detection

Transmission output

RS485 communication (MODBUS)

Main Function

Defrosting (auto / manual)

Defrosting stop delay

Evaporation fan control

Air inlet/outlet sensor: 2EA

Defrost recovery sensor: 1EA

Virtual temperature sensor computing

Door open alarm

Emergency call

Night operation

High (low) temperature alarm output

RS485 communication (MODBUS)

Main Function

Defrosting (auto / manual)

Defrosting stop delay

2 air inlet/outlet sensors

One sensor for defrost recovery

High / Low alarm output

Indicator (FixView) connection

RS485 communication (MODBUS)

Main Function

Heating / cooling output

Independent timer output

High / Low alarm output

Defrost output

Precise temperature control

Sensor correction

Sensor error detection

Data back up

Minimum on/off maintaining time setup

RS485 communication (MODBUS)

Transmission output

Auto-output operation cycle settable in case of sensor error

Features

Humidification (heating)

Dehumidification (cooling) output

High/Low alarm output

Min. on/off maintaining time setup

Selection on/off output when sensor error occurs

Sensor correction

Sensor error detection

Relay output manual control

Transmission output

RS485 communication (MODBUS)

Main Function

Heating / cooling output

Independent timer output

High / Low alarm output

Defrost output

Precise temperature control

Sensor correction

Sensor error detection

Data back up

Minimum on/off maintaining time setup

RS485 communication (MODBUS)

Transmission output

Auto-output operation cycle settable in case of sensor error

Main Function

Humidification/dehumidification output

High/Low alarm output

Min. on/off maintaining time setup

Selection on/off output when sensor error occurs

Sensor correction

Sensor error detection

Selection of displaying decimal point

Main Function

Heating / cooling output

High / Low alarm output

Precise temperature control

Sensor correction

Sensor error detection

Data back up

Minimum on/off maintaining time setup

RS485 communication (MODBUS)

Transmission output

Main Function

Heating / cooling output

Precise temperature control

Sensor correction

Sensor error detection

Data back up

Minimum on/off maintaining time setup

Auto-output operation cycle settable in case of sensor error

Main Function

Heating/cooling output

High / Low alarm output

Precise temperature control.

Sensor correction, sensor error detection

Sensor error detection

Data backup

Min. on/off maintaining time setup

Transmission output

RS485 communication (MODBUS)

Main Function

Heating / cooling output

Independent timer output

High / Low alarm output

Precise temperature control

Sensor correction

Sensor error detection

Data back up

Minimum on/off maintaining time setup

RS485 communication (MODBUS)

Transmission output

Features

Uses a multi-fin, centrifugal level vertical heat exchange circulation system; ventilation rate can be adjusted to the desired rate.

Internal rotating pan can be convenient removed and installed, the motor rotating speed of hang shelf is 8-10 rpm.

A digital watt/hour meter and timer can be used to present the air refresh rate.

Features

Panel Dimension: 1.5" - 3.4"; 14.1" - 42"

CLCD-9700 Color touch panel controller was made in Japan

Forced air in and out to control the loading of specimen

Wider viewing glass design and have a connecting to safety protection device

Easily changed design as your product changes

Features

Measured parameters: carbon dioxide, temperature, and humidity (optional)

Superior long-term stability with the latest-generation Vaisala CARBOCAPâ sensor

Accurate temperature and humidity measurements due to the low-power microglow infrared source

Quick and easy installation and maintenance

Calibrated, user-exchangeable measurement modules

23-point traceable CO2 calibration (certification included)

Both analog and field bus communication (Modbusâ RTU)

Features

Adopt computerized electronic digital control, precise & reliable.

The packing of box insulation is molded by silicone, high-temperature enduring & never aged attached with observation view window, easy to be used

Heating is by compulsory circulating ventilation, temperature raising is fast and spread even

Provide the P.I.D control system, double sided overheating protection, safe & reliable.

Easy to set temperature, easier to operate

Attached with two sets of moveable disks to be adjusted high and low at your dispel

Features

Made entirely of P.P & PVC, resistant to acids, bases and heat. It can be used with salt spray acetic acid, or any other testing material.

Patented nozzle and conical dispersion unit ensure even spraying rate

It can be controlled manually, or for up 9,991 hours of operation

At the end of the experiment, a defogger automatically cleans the inside of the testing chamber for specimen.

Three set temperature controlling systems of air-tank temperature, test area temperature, solution temperature. To make sure the correctness amd standard of the testing.

Features

T-Bar Design

1-Second Measuring Interval

Max. - Min. Function

Auto Off-Function

Water-Tight

Protective cover and pocket clips included

Features

System capacity: It could sign in 150 programs x 1500 partitions, partitions can be optionally divided and program can link up to each other.

Loop configuration: 9999 x 999 looping time, can be divided into 5 independent sub-loops

Output: Intelligent PID + SSR/ SCR two-way synchronous output, built-in advanced slope control logic

Data: Touch panel dialogue box display, easy operation, built-in managemnet system of data content

Curves drawing: When temperature, humidity and times are set up, the data can be immediately transferred into curves, actual operating curves can be attained during operations

Features

On desk design affords small volume with occupying space

All programmed instructions are microprocessor-controlled. with PID and automatic calculation to ensure precise and stable temperature and humidity control.

In the case of thermostat breakdown, a warning light switches on and temperature setting is changed to standard

Heat is evenly distributed throughout the testing chamber to ensure a uniform testing temperature

Features

The design mode of these sets is one body affords convenient application and less space occupation.

It can separately test high temperature and constant temperature and humidity.

All systems are individual and independent. The three sets type of the refrigstion system and three sets of the type heating and humidifying systems are adopted. The three set type systems afford stable control and high accuracy, prolonging the service life machine parts.

All programmed instructions are microprocessor-controlled, with PID and automatic calculation to ensure precise and stable temperature and humidity control.

Features

This equipment features independent systems with vibration control and cross-temperature and cross-humidity controls. It can be set to test and display results for high temperatures, low temperatures, cross temperatures and humidity and vibration, either individually or at the same time.

Moveable guide rails for easy testing separately or simultaneously.

Large LCD display in Chinese or English plus 100-program memory and standard RS-232C computer interface.

Page load link

Features

Features Features

Features Main Function

Main Function Main Function

Main Function Main Function

Main Function Main Function

Main Function Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features