- Nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar

- Accuracy: 0.5 % FSO

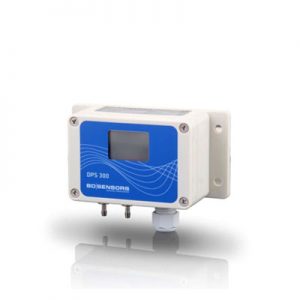

- Indication of measured values on a 4-digit LED display

- Rotatable and configurable display module

- 1, 2 or 4 independent PNP contacts, freely configurable

- IS-version: Ex ia = intrinsically safe for gases

- Pressure port PVDF

- Customer specific versions

- Mechanical and Plant Engineering

- Environmental Industry