Skip to content

-

Characteristics

- Nominal pressure range from 0 ... 2 000 bar up to 0 ... 6 000 bar

- Stainless Steel Sensor (Strain Gauge), Oil & Gas

- Accuracy according to IEC 60770:

standard: 0.5 % FSO

option: 0.25 % FSO

-

Characteristics

- Stainless Steel Sensor

- Universal Application

- Nominal pressure from 0 ... 100 mbar up to 0 ... 600 bar

- Accuracy according to IEC 60770:

standard: 0.25 % FSO

option: 0.1 % FSO

-

Characteristics

- Stainless Steel Sensor

- Universal Application

- Nominal pressure ranges from 0...100mBar Up To 60 bar

- Accuracy according to IEC 60770:

standard: 0.35 % FSO

option: 0.25 / 0.1 % FSO

-

Characteristics

- Process Connections with Flush Welded Stainless Steel Diaphragm

- Hygienical Application

- Nominal pressure range from 0...100 mbar Up To 40 bar nominal pressure

- Accuracy according to IEC 60770: 0.1 % FSO

-

Characteristics

- Stainless Steel Sensor

- Universal Application

- Nominal pressure from 0 ... 100 bar up to 0 ... 600 bar

- Accuracy according to IEC 60770:

standard: 0.35 % FSO

option: 0.25 / 0.1 % FSO

-

Characteristics

- Thinfilm Sensor

- Nominal pressure range from 0 ... 600 bar up to 0 ... 2200 bar

- Accuracy according to IEC 60770: 0.35 % FSO

- Preferred areas of use for Plant & Mechanical Engineering

-

Characteristics

- Welded, Dry Stainless Steel Sensor

- Nominal pressure range from 0 ... 6 bar up to 0 ... 600 bar

- Accuracy according to IEC 60770: 0.5 % FSO

- Preferred areas of use for Medical Technology

-

Characteristics

- Stainless Steel Sensor Flush Version G 1/4

- Nominal pressure ranges from 0 ... 60 bar to 0 ... 600 bar

- Accuracy according to IEC 60770: 0.35 % FSO

-

Characteristics

- Stainless Steel Sensor, Without Media Isolation, HVAC

- Nominal pressure ranges from 0 ... 10 mbar up to 0 ... 1000 mbar

- Accuracy according to IEC 60770: 0.35 % FSO

-

Characteristics

- Stainless Steel Sensor

- Nominal pressure ranges from

- Accuracy according to IEC 60770:

standard: 0.35 % FSO

option: 0.25 % FSO

-

Characteristics

- Stainless Steel Sensor

- Nominal pressure from 0 ... 400 mbar up to 0 ... 600 bar

- accuracy according to IEC 60770: 0.1 % FSO

- Preferred areas of use for Process, Oil And Gas Industry

- Communication interface for adjusting of offset, span and damping

-

Characteristics

- Stainless Steel Sensor, With Fast Response

- Nominal pressure ranges from 0...100 mbar up to 0...600 bar

- Accuracy according to IEC 60770: 0.1 % FSO

-

Characteristics

- Pressure Ports and Process Connections with Flush Welded Stainless Steel Diaphragm

- Nominal pressure ranges from 0 ... 400 mbar up to 0 ... 40 bar

- Accuracy according to IEC 60770: 0.1 % FSO

-

Characteristics

- Thinfilm Sensor

- Nominal pressure ranges from 0 ... 600 bar up to 0 ... 2200 bar

- Accuracy according to IEC 60770: 0.1 % FSO

- Preferred areas of use for Welded, Plant And Machine Engineering

-

Characteristics

- Ceramic Sensor

- Nominal pressure ranges from 0 ... 160 mbar up to 0... 20 bar

- Accuracy according to IEC 60770: 0.1 % FSO

- Preferred areas of use for Flush, Hygienical Application

-

Characteristics

- Stainless Steel Sensor

- Nominal pressure ranges from 0 ... 400 mbar up to 0 ... 40 bar

- Accuracy according to IEC 60770: 0.1 % FSO

- Preferred areas of use for Flush, Hygienical Application

-

Characteristics

- Ceramic Sensor

- Nominal pressure ranges from 0 ... 160 mbar up to 0... 20 bar

- Accuracy according to IEC 60770: 0.1 % FSO

- Preferred areas of use for Process, Oil And Gas Industry

-

Characteristics

- Stainless Steel Sensor

- Nominal pressure ranges from 1 mbar up to 20 bar

- Accuracy according to IEC 60770: 0.075 % FSO

- Preferred areas of use are Process, Oil And Gas Industry

-

Characteristics:

- Stainless Steel Sensor, Plant And Mechanical Engineerin

- Differential pressure ranges from 0 ... 20 mbar up to 0 ... 16 bar

- Accuracy according to IEC 60770: 0.5 % FSO

-

Characteristics:

- Silicon Sensor, Plant And Mechanical Engineering

- Differential l pressure ranges from 0 ... 6 mbar up to 0 ... 1000 mbar

- accuracy according to IEC 60770: 0.35 % / 1% / 2%

-

Characteristics:

- 2 piezoresistive stainless steel sensors

- Differential pressure from 0 ... 1 bar up to 0 ... 70 bar

- Display and pressure port rotatable

-

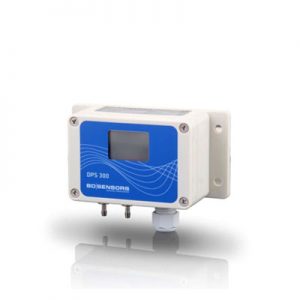

Characteristics

- Piezoresistive silicon sensor

- Differential pressure range 6 ... 1000 mbar

- Application for for HVAC-applications

-

Characteristics:

- Silicon Sensor, HVAC Medical

- Differential pressure ranges from 0 ... 1.6 mbar up to 0 ... 1000 mbar

- Accuracy according to IEC 60770: 0.5% FSO BFSL

-

Characteristics:

- Stainless Steel Sensor, Test Engineering, Machine And Plant Engineering

- Differential pressure ranges from from 10 mbar up to 20 bar

- Accuracy according to IEC 60770: 0.35 % FSO

-

Features

- Nominal pressure: 0 ... 2 bar up to 0 ... 400 bar

- Accuracy: 1 % FSO

- 1 or 2 contacts

- Configurable via PC or programming device P6

- Diaphragm ceramic (96 %)

Optional Features

- Oil- and grease free application

Areas of Application

- Mechanical and plant engineering

- Energy Industry

-

Characteristics:

- Stainless Steel Sensor

- nominal pressure ranges from 0 ... 100 mbar up to 0 ... 600 bar

- Accuracy according to IEC 60770: Standard: 0.35 % FSO option: 0.25 % FSO

-

Features

- Nominal pressure: 0 ... 100 mbar up to 0 ... 40 bar

- Accuracy: 0.35 % (opt. 0.25 %) FSO

- Rotatable and configurable display module

- Indication of measured values on a 4-digit LED display

- 1, 2 or 4 independent PNP contacts, freely configurable

- Configurable contacts (switch on / switch off points, hysteresis / window mode, switch on / switch off delay)

Optional Features

- IS-version : Ex ia = intrinsically safe for gases

- Customer specific versions

- Analogue output

Areas of Application

- Medical Technology

- Food and Beverage

-

Features

- Nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar

- Accuracy: 0.5 % FSO

- Indication of measured values on a 4-digit LED display

- Rotatable and configurable display module

- 1, 2 or 4 independent PNP contacts, freely configurable

Optional Features

- IS-version: Ex ia = intrinsically safe for gases

- Pressure port PVDF

- Customer specific versions

Areas of Application

- Mechanical and Plant Engineering

- Environmental Industry

-

Features

- Nominal pressure: 0 ... 60 bar up to 0 ... 400 bar

- Accuracy: 0.5 % FSO

- 1, 2 or 4 independent PNP contacts, freely configurable

- Rotatable and configurable display module

- Indication of measured values on a 4-digit LED display

Optional Features

- IS-version - Ex ia = intrinsically safe for gases

- Cooling element up to 300°C

- Customer specific versions

Areas of Application

- Mechanical and Plant Engineering

- Food and Beverage

-

Features

- Nominal pressure: 0 ... 6 bar up to 0 ... 600 bar

- Accuracy: 0.5 % FSO

- Indication of measured values on a 4-digit LED display

- Rotatable and configurable display module

- 1, 2 or 4 independent PNP contacts, freely configurable

Optional Features

- IS-version: Ex ia = intrinsically safe for gases

- Oxygen application

- Customer specific versions

Areas of Application

- Mechanical and Plant engineering

- Energy Industry

- Refrigeration Engineering

- Medical Technology

- Utility Vehicles / Mobile Hydraulics

-

Features

- Nominal pressure: 0 ... 10 mbar up to 0 ... 1000 mbar

- Accuracy: 0.35 % FSO

- Indication of measured values on a 4-digit LED display

- Rotatable and configurable display module

- 1, 2 or 4 independent PNP contacts, freely configurable

Optional Features

- IS-version: Ex ia = intrinsically safe for gases

- Customer specific versions

Areas of Application

- Mechanical and Plant Engineering

- HVAC

- Laboratory

-

Features

- Nominal pressure: 0 ... 600 bar up to 0 ... 2200 bar

- Accuracy: 0,35 % FSO

- Indication of measured values on a 4-digit LED display

- Rotatable and configurable display module

- 1, 2 or 4 independent PNP contacts, freely configurable

- Pressure sensor welded

- Extremely robust and excellent longterm stability

Optional Features

- Adjustability of span and offset (4 ... 20 mA / 3-wire)

- Customer specific versions

Areas of Application

- Mechanical and Plant Engineering

- Utility Vehicles / Mobile Hydraulics

-

Features

- Nominal pressure: 0 ... 6 bar up to 0 ... 600 bar

- Accuracy: 0.5 % FSO

- 1 analog output and up to 2 contacts

- Display and housing rotatable

- Perfect for oxygen applications

Areas of Application

- Mechanical and Plant Engineering

- Energy Industry

- Refrigeration Engineering

- Medical Technology

- Utility Vehicles / Mobile Hydraulics

-

Features

- Nominal pressure: 0 ... 2 bar up to 0 ... 400 bar

- Accuracy: 1.5 % FSO

- Display and housing rotatable

- Up to 2 contacts

- Configurable via display

Optional Features

Areas of Application

- Mechanical and Plant Engineering

- Energy Industry

-

Features

- Nominal pressure: 0 ... 6 mbar up to 0 ... 1000 mbar

- Accuracy: 0,35 % FSO

- Aluminum housing

- Rotatable and configurable display module

- 4-digit LED display

- Suited for non-aggressive gases and compressed air

Optional Features

- 1 / 2 PNP contacts

- customer specific versions

Areas of Application

- Mechanical and plant engineering

- HVAC

-

Features

- Nominal pressure: 0 ... 100 mbar up to 0 ... 600 bar

- Accuracy: 0,35 % FSO

- Analog output (optional): 4 ... 20 mA or 0 ... 10 V

- Indication of measured values on a 4-digit LED display

- Parametrization by IO-Link or set menu system (VDMA-conform)

- Rotatable and configurable display

- 2 contacts

Optional Features

- different mechanical connections

- customer specific versions

Areas of Application

- Mechanical and Plant Engineering

- Hydraulics

- Packaging and Paper Industry

Page load link

Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features Features

Features